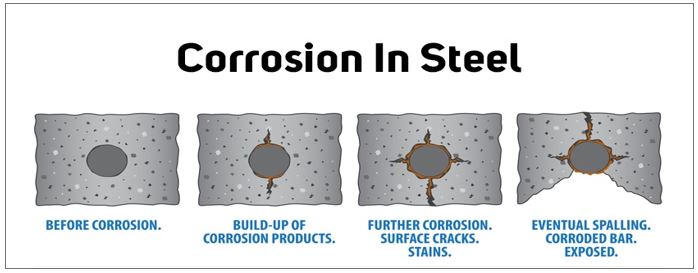

In the realm of infrastructure development, the construction of dams and canals holds paramount importance for water management, hydroelectric power generation, and irrigation systems. However, the constant exposure of these structures to marine environments poses a significant challenge: the corrosion of reinforcing steel due to chloride ion migration.

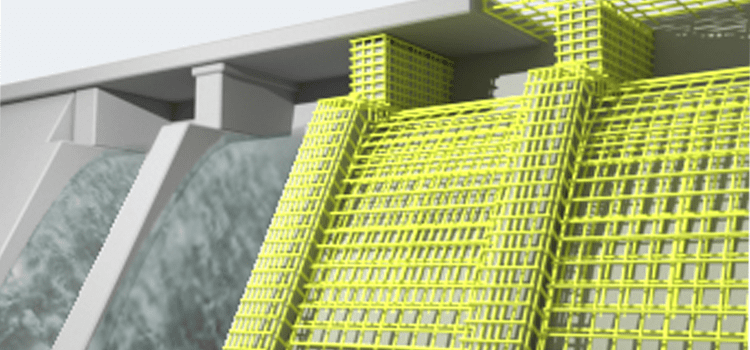

To combat this pervasive issue, SuperBars™ introduces an optimal solution – Glass Fiber Reinforced Polymer (GFRP) rebars. In this blog post, we will explore how GFRP rebars revolutionise the construction of dams and canals by offering corrosion-free reinforcement, promoting longevity, and driving sustainable practices.

Deterioration of reinforced concrete structures in marine environments due to chloride ion migration is a critical concern affecting infrastructure projects globally. Traditional solutions to control corrosion involve methods like cathodic protection and increasing the thickness of the concrete cover. While effective to a certain extent, these solutions often add substantial weight to the structure, necessitate frequent maintenance, and incur higher costs.

GFRP rebars have emerged as an innovative and transformative solution in the construction industry. These rebars are manufactured by combining high-strength glass fiber with a polymer matrix, resulting in a composite material that offers outstanding performance characteristics. The unique composition of GFRP rebars renders them impervious to corrosion, making them an ideal choice for reinforcing concrete in marine environments.

The corrosion-resistant nature of GFRP rebars is a game-changer in the construction of dams and canals, where exposure to moisture and chloride ions is inevitable. Unlike traditional steel reinforcement, GFRP rebars do not rust or corrode, ensuring the structural integrity and longevity of these critical infrastructure projects.

The combination of high-strength glass fibers and polymer resins in GFRP rebars results in a rebar that offers exceptional tensile strength comparable to traditional steel reinforcement. This strength translates to robust and reliable reinforcement that can withstand the demanding conditions of dam and canal construction.

Furthermore, GFRP rebars possess excellent dimensional stability, maintaining their shape and performance over time. They are not affected by temperature changes or moisture absorption, minimising the risk of cracks, expansion, or contraction that can compromise the structural integrity of concrete elements.

In addition to their corrosion resistance and strength, GFRP rebars offer other significant advantages. Their non-magnetic and non-conductive properties make them suitable for projects that require minimal electrical or magnetic interference, such as hydroelectric power plants and communication infrastructure along canals.

The lightweight nature of GFRP rebars further enhances their suitability for dam and canal construction. With a weight approximately 75% lighter than traditional steel rebars, GFRP rebars facilitate easier handling, transportation, and installation. This weight reduction not only improves construction efficiency but also reduces the overall load on the structure, contributing to its stability and longevity.

Advantages of GFRP Rebars in Dam and Canal Construction:

Corrosion Resistance: The exceptional corrosion resistance of GFRP rebars eliminates the risk of rust and degradation, ensuring the longevity and structural integrity of dams and canals. This attribute significantly reduces the need for maintenance and repair over the lifespan of the structure, leading to cost savings.

Lightweight and High Strength: GFRP rebars weigh approximately 75% less than traditional steel rebars while maintaining comparable tensile strength. This characteristic simplifies transportation, handling, and installation, resulting in improved construction efficiency and reduced labour requirements. Furthermore, the lightweight nature of GFRP rebars minimises the load on the structure, contributing to its overall stability.

Non-Magnetic and Non-Conductive: GFRP rebars exhibit non-magnetic and non-conductive properties, making them ideal for environments where electrical conductivity or magnetic interference must be minimised. This feature is particularly advantageous in dam and canal construction near power lines, sensitive equipment, or areas requiring electromagnetic neutrality.

Design Flexibility: GFRP rebars offer enhanced design flexibility, allowing for on-site customization to fit complex structural designs. Unlike traditional steel rebars, GFRP rebars can be easily cut and bent, facilitating precise fitting and enabling architects and engineers to create innovative and efficient structures.

Sustainable Construction: GFRP rebars contribute to sustainable construction practices in multiple ways. Firstly, the manufacturing process of GFRP rebars requires significantly less energy and generates fewer carbon emissions compared to steel reinforcement. Secondly, GFRP rebars are fully recyclable at the end of their lifespan, minimising environmental impact and promoting a circular economy. By incorporating GFRP rebars, construction projects can align with sustainability goals and reduce their ecological footprint.

The Competitive Edge: GFRP Rebars vs. Steel Rebars:

When comparing GFRP rebars to traditional steel rebars, several factors come into play. While GFRP rebars may have a higher upfront cost, their long-term benefits outweigh the initial investment. GFRP rebars’ corrosion-free nature eliminates the need for expensive and frequent maintenance, leading to substantial cost savings over the structure’s lifetime. Additionally, the lightweight nature of GFRP rebars reduces transportation and labour costs, further enhancing the overall cost-effectiveness of using GFRP rebars in dam and canal construction.

Partnering with SuperBars™ – A Trusted GFRP Manufacturer:

SuperBars, a leading manufacturer of GFRP rebars, stands as a trusted partner in the construction industry. With state-of-the-art manufacturing facilities and a commitment to delivering high-quality products, SuperBars provides reliable and durable reinforcement solutions for dams and canals. Our expertise in GFRP rebar manufacturing, coupled with a focus on sustainability and innovation, ensures that construction projects benefit from the best-in-class materials and achieve long-lasting results.

GFRP rebars offer an optimal solution for addressing the corrosion challenges faced in the construction of dams and canals. With their exceptional corrosion resistance, lightweight nature, and sustainable properties, GFRP rebars provide a reliable and durable alternative to traditional steel reinforcement.

By choosing GFRP rebars, construction professionals can enhance the longevity and performance of infrastructure projects, while contributing to sustainable practices and minimising maintenance costs. SuperBars, as a trusted GFRP manufacturer, remains committed to driving innovation and excellence in the construction industry, paving the way for a future of robust and sustainable infrastructure.