In the dynamic realm of construction, innovation is the driving force that shapes the way we build our world. Today, countries across the world are leveraging a revolutionary solution – Glass Fiber Reinforced Polymer (GFRP) rebars – to transform construction practices, enhancing strength, reducing costs, and promoting environmental sustainability. We, at SuperBars™ , understand the potentiality of having GFRP Rebars for a more efficient and eco-friendly construction landscape and constantly explore their diverse applications.

Economic Efficiency: Rethinking Construction Costs

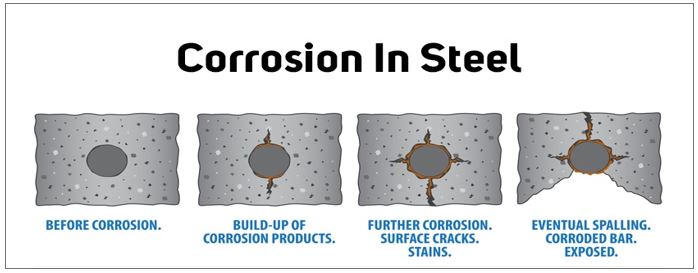

In the world of construction, balancing budget constraints with durability has always been a critical challenge. The emergence of GFRP rebars introduces a fresh perspective, redefining the economic equation of building projects. While the initial investment in GFRP rebars may be slightly higher compared to conventional steel rebars, the long-term financial benefits they offer are substantial. GFRP rebars are highly resistant to corrosion and wear, leading to significantly reduced maintenance costs over the lifecycle of a structure. The prospect of fewer repairs and replacements positions GFRP rebars as a cost-effective choice in the long run.

Consider the colossal Sheikh Jaber Al-Ahmad Al-Sabah Causeway in Kuwait – a project that exemplifies the economic advantages of GFRP rebars. Spanning over 30 kilometres, this marvel demonstrates the potential for substantial cost savings due to reduced maintenance needs. By choosing GFRP rebars, the project ensured both enduring structural integrity and remarkable economic viability.

Environmental Responsibility: A Greener Construction Approach

Amid growing environmental concerns, the construction industry is turning towards sustainable practices. Traditional steel rebars, while robust, contribute significantly to carbon emissions due to energy-intensive manufacturing

processes. In contrast, GFRP rebars offer an eco-friendly alternative, emitting fewer greenhouse gases during production. The inherent corrosion resistance of GFRP rebars also means fewer replacements, resulting in less waste generation over time.

Take the iconic Pulaski Skyway Rehabilitation Project in the United States as an example. By opting for GFRP rebars, the project demonstrated a commitment to environmental stewardship. Beyond enhancing durability, the choice aligned with sustainable construction practices, underscoring the importance of minimising ecological impact for a more sustainable future.

SuperBars™: Leading the Innovation Wave

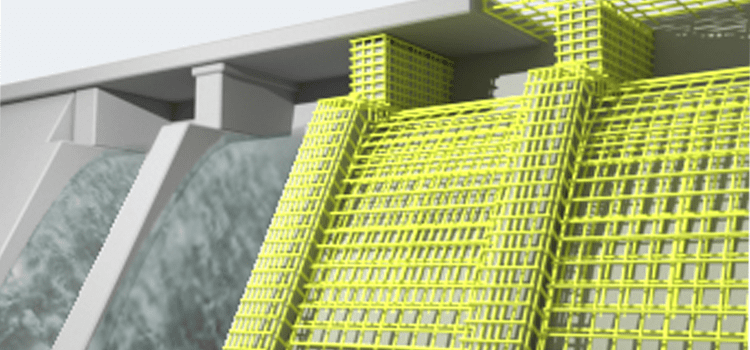

At the heart of the GFRP rebar revolution is SuperBars™, dedicated to excellence in both production and sustainability, showcasing cutting-edge technology and exceptional mechanical properties. The fusion of glass fibres and polymer resin results in rebars that deliver unrivalled structural strength.

We, at SuperBars™, try to extend our influence beyond manufacturing and offer a range of services that cater to the unique needs of each project. From expert consultations to structural optimization through engineering codes, the team collaborates closely with clients to ensure that the advantages of GFRP rebars are maximised.

Conclusion: Shaping a Future of Strength and Sustainability

In a world where construction decisions have far-reaching implications, GFRP rebars emerge as a transformative force. Embracing these rebars help in embarking on a journey towards enhanced economic viability and environmental consciousness. The convergence of strength, cost-effectiveness, and reduced environmental impact is reshaping construction paradigms and to know how we, at SuperBars™, understand the industry importance of GPRF Rebars, visit our website.

To explore further about pioneered GFRP rebars, SuperBars™ and their impact on construction, visit https://super-bars.com/.

Discover firsthand how GFRP rebars are redefining construction practices globally, driving us towards a future where structures stand as testaments to both human ingenuity and responsible environmental practices.