Government contractors play a crucial role in developing and maintaining infrastructure projects. To ensure the longevity, safety, and sustainability of these structures, it is essential to choose the right construction materials. In recent years, GFRP (Glass Fiber Reinforced Polymer) rebars have emerged as a game-changer in the construction industry. In this article, we will explore how government contractors can benefit from incorporating GFRP rebars in their infrastructure projects. From cost savings to durability and environmental advantages, GFRP rebars offer a compelling solution that aligns with the goals of government projects.

Understanding GFRP Rebars:

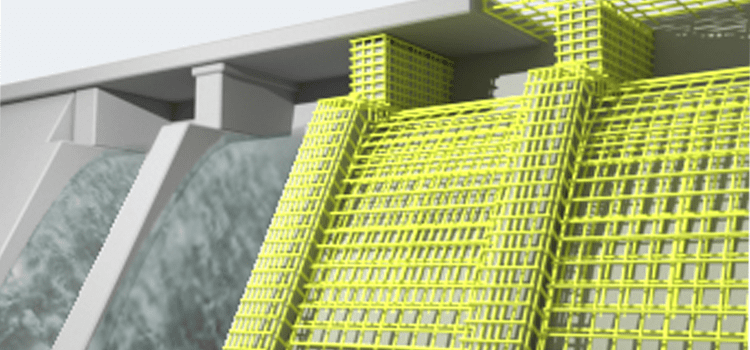

GFRP rebars are composite materials made of high-strength glass fibres embedded in a polymer matrix, typically resin. These rebars possess exceptional strength-to-weight ratio, making them an ideal alternative to traditional steel rebars. The glass fibres provide excellent tensile strength, while the polymer matrix offers resistance to corrosion and chemical degradation. This unique composition makes GFRP rebars lightweight, durable, and highly corrosion-resistant, addressing some of the key challenges faced by government contractors in infrastructure projects.

Enhanced Durability for Long-Lasting Structures:

Government infrastructure projects require structures that can withstand the test of time. One of the significant benefits of GFRP rebars is their superior durability compared to conventional steel rebars. GFRP rebars are inherently corrosion-resistant, which eliminates the risk of concrete spalling and structural degradation caused by rusting. As a result, infrastructure projects reinforced with GFRP rebars have a longer service life, reducing maintenance and repair costs in the long run. This durability factor is especially critical for government contractors responsible for building and maintaining bridges, highways, and other infrastructure assets.

Cost Savings and Efficiency:

Government projects often operate within strict budgets, making cost-effectiveness a key consideration. GFRP rebars offer significant cost savings over traditional steel rebars. Although the initial material cost of GFRP rebars may be slightly higher, the overall project cost can be reduced due to their lightweight nature. GFRP rebars are much lighter than steel rebars, which makes transportation and installation more efficient. Contractors can handle larger lengths of GFRP rebars per shipment, reducing logistics expenses. Additionally, the lighter weight facilitates faster installation, resulting in reduced labour costs and shorter project timelines.

Environmental Sustainability:

Sustainability is a growing concern for government infrastructure projects. GFRP rebars contribute to environmental sustainability in several ways. First, the manufacturing process of GFRP rebars requires fewer resources and emits fewer greenhouse gases compared to the production of steel rebars. Second, the corrosion-resistant properties of GFRP rebars result in longer-lasting structures, reducing the need for frequent repairs and replacements. This translates into a smaller carbon footprint over the lifespan of the infrastructure. By choosing GFRP rebars, government contractors can demonstrate their commitment to sustainable construction practices and contribute to a greener future.

Applications and Success Stories:

GFRP rebars have been successfully utilised in various government infrastructure projects worldwide. From bridge decks and retaining walls to marine structures and wastewater treatment plants, GFRP rebars offer versatile reinforcement solutions. For example, in a recent government-funded bridge project, the implementation of GFRP rebars resulted in extended service life and reduced maintenance costs. Similarly, GFRP-reinforced wastewater treatment plants have demonstrated exceptional resistance to chemical attack and corrosion, ensuring long-term functionality and cost savings.

Government contractors have a responsibility to deliver infrastructure projects that are durable, cost-effective, and sustainable. By embracing GFRP rebars, contractors can benefit from enhanced durability, cost savings, and environmental advantages. The inherent corrosion resistance and lightweight nature of GFRP rebars contribute to longer-lasting structures, reduced maintenance costs, and improved project efficiency.

Furthermore, the adoption of GFRP rebars aligns with sustainable construction practices, demonstrating the commitment of government contractors towards environmental stewardship. As the construction industry continues to evolve, GFRP rebars present an exciting opportunity for government contractors to advance infrastructure projects and create a sustainable future for generations to come.