From towering skyscrapers to intricate bridges, the materials and techniques employed shape the infrastructure of our future. Glass Fiber Reinforced Polymer (GFRP) rebars have emerged as a revolutionary alternative to traditional steel, capturing the attention of industry leaders and experts worldwide. This article delves into the myriad applications of GFRP rebars in various construction streams, as we understand at SuperBars , highlighting the endorsement of Shri Nitin Gadkari, India’s Minister of Road Transport and Highways.

Versatility of GFRP Rebars:

Reinventing Foundations: Civil Engineering Projects

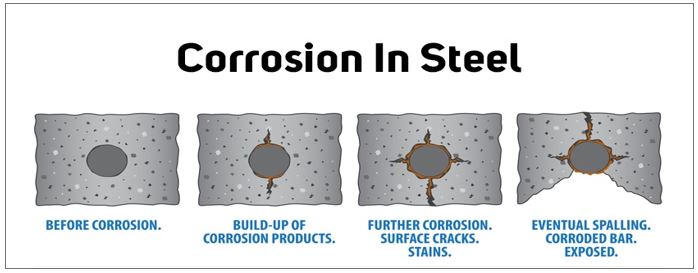

GFRP rebars have transformed civil engineering projects, from bridges to highways and beyond. Their lightweight nature simplifies transportation and handling, while their corrosion resistance ensures enduring structures that require minimal maintenance. By embracing GFRP rebars, engineers can create resilient infrastructure that stands the test of time, all while reducing the carbon footprint.

Projects where the National Highways Authority of India (NHAI) has used GFRP Rebars:

- Flyovers in the Mumbai-Pune Expressway: NHAI utilised GFRP rebars in the rehabilitation and retrofitting of multiple flyovers along the Mumbai-Pune Expressway.

- Thiruvananthapuram Bypass Tunnel, Kerala: The rebars were used to reinforce the tunnel lining, ensuring its stability and longevity while withstanding the environmental challenges of the region.

- Pune-Nashik Highway Widening Project

Taking to the Skies: Aviation and Aerospace Construction

In the aerospace industry, weight is a critical factor. GFRP rebars’ exceptional strength-to-weight ratio makes them a prime choice for constructing hangars, runways, and even aircraft components. Their resistance to corrosion and electromagnetic neutrality further contribute to the reliability and safety of aviation infrastructure.

Few aviation projects where the Government of India used GFRP Rebars:

- Helipad Construction: Several government helipads, including those used for emergency medical services and government officials’ transportation, have integrated GFRP rebars. These rebars ensured the durability and strength of the helipad landing surfaces.

- Bengaluru International Airport: The construction of aircraft parking aprons at the Bengaluru International Airport saw the integration of GFRP rebars.

- Hindustan Aeronautics Limited (HAL) Facilities: HAL, a premier aerospace company, incorporated GFRP rebars in the construction of hangars and aircraft maintenance facilities.

Beneath the Waves: Marine and Offshore Projects

Marine and offshore environments subject structures to harsh conditions, including saltwater exposure and corrosive elements. GFRP rebars, impervious to corrosion, become a formidable ally in building docks, piers, and offshore platforms. Their durability ensures the longevity of these vital structures, reducing maintenance costs and environmental impacts.

The Government of India encouraged the usage of GFRP Rebars in marine projects:

- Mumbai Coastal Road Project: The rebars’ resistance to corrosion ensured the durability of these structures in the challenging marine environment.

- Kochi International Container Transshipment Terminal: The construction of the terminal saw the incorporation of GFRP rebars in the reinforcement of concrete structures. The rebars’ resistance to saltwater corrosion was crucial in ensuring the structural integrity of the terminal’s marine infrastructure.

- Andaman and Nicobar Islands Development: In the development of infrastructure on remote islands, GFRP rebars were used to reinforce marine and offshore structures. These rebars helped withstand the island’s challenging coastal environment.

Building Sustainability: Green Construction Initiatives

As the world shifts towards sustainable practices, GFRP rebars shine as a beacon of eco-friendliness. Their lower carbon footprint, combined with their energy-efficient properties, align seamlessly with green construction initiatives. From eco-friendly residential buildings to LEED-certified commercial complexes, GFRP rebars play a pivotal role in reducing the construction industry’s environmental impact.

The Government of India (GOI) used GFRP rebars for green construction projects like:

- Smart Cities Mission: Under the Smart Cities Mission, the GOI has incorporated GFRP rebars in the construction of sustainable urban infrastructure.

- Renewable Energy Projects: In the construction of renewable energy projects such as solar power installations and wind energy structures, GFRP rebars have been employed.

- Eco-Tourism Initiatives: The development of eco-tourism destinations involves the use of sustainable construction materials. GFRP rebars have been used in the construction of lodging facilities, viewing platforms, and other structures that prioritise environmental sustainability.

Embracing Creativity: Architectural Marvels

Architects are embracing the flexibility of GFRP rebars to bring their visionary designs to life. These rebars can be moulded into intricate shapes, enabling the creation of aesthetically stunning and structurally sound buildings. From futuristic facades to artistic sculptures, GFRP rebars offer architects an expansive canvas for their creativity.

Shri Nitin Gadkari’s Stamp of Approval: A Paradigm Shift in Indian Construction

India’s Minister of Road Transport and Highways, Nitin Gadkari, has not only endorsed but actively encouraged the use of GFRP rebars in lieu of traditional steel. This visionary stance is a testament to the transformative potential of GFRP rebars in the Indian construction landscape. Gadkari recognizes the multifaceted benefits of GFRP rebars, from cost-efficiency to sustainability, and their ability to revolutionise the way infrastructure is built and maintained.

Take a look at a snippet of what Hon’ble Nitin Gadkari sir has got to say about GFRP Rebars.

SuperBars™: Pioneering the GFRP Rebar Revolution

At the forefront of the GFRP rebar revolution stands SuperBars™, a trailblazer in innovation, quality, and transformation that has brought GFRP rebars into the spotlight. With cutting-edge technology, precision engineering, and our unwavering commitment to pushing the boundaries of construction materials, we, at SuperBars™, produce GFRP rebars that boast exceptional mechanical properties, setting new industry standards.

Conclusion:

The rise of GFRP rebars marks a pivotal moment in the construction industry’s trajectory. From enhancing structural integrity to promoting sustainability, GFRP rebars have earned their place as a game-changing material in various construction streams. Shri Nitin Gadkari’s endorsement further underscores their significance, while SuperBars™ continues to lead the charge in propelling the GFRP rebar revolution forward. As the world of construction embraces innovation, GFRP rebars stand tall as a beacon of progress and possibility.